Product Qualification and Compliance

To guarantee the highest level of workmanship our production units are comprised of fully qualified specialists. Also, our product qualification processes ensure that your products fully meet your requirements.

To guarantee the highest level of workmanship our production units are comprised of fully qualified specialists. Also, our product qualification processes ensure that your products fully meet your requirements.

Microweld organization controlled by a management system certified by ISO 13485, ISO 9001 and EN 9100 standards.

The certifications were renewed under the versions:

Microwelding is a very specialised process which requires a specific qualification processes to ensure that the final products meets all usage and safety requirements.

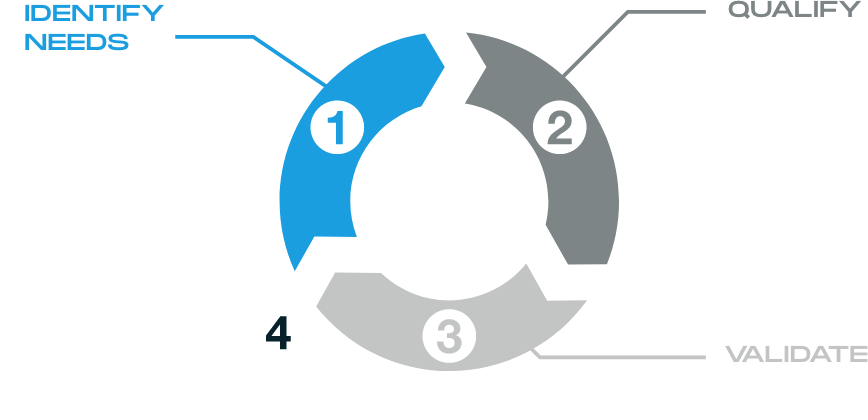

Our four stage qualification process ensures that the properties of our welds comply with your specifications, the mechanical characteristics, the resistances of the various modes of stress, embrittlement and dynamic behavior.

Define the technical requirements and specificities.

Qualify your products and our resources to meet your requirements.

Check that the treatment applied to the part actually meets the definition requirements by testing.

Monitor and measure effectiveness

Our teams in our metrology laboratory use several methods of control